Our dedicated team can help customize and design a plan to meet your specific project needs. KBS engineers are experts in modular design and can execute technically complex and challenging designs.

Modules are fabricated using a balance of technology and skilled tradespeople at one of our climate-controlled factories in Maine under strict quality control guidelines. Factory construction occurs concurrently with project site preparation.

Once factory construction is complete, we carefully manage the logistics to ensure the proper handling, shipping and delivery of your modular units to the project site.

Our team of modular experts work with the builder to erect your modular units on-site and prepare the project for the final inspection and occupancy.

Concurrent on-site and off-site process cuts standard project timelines by 25-50%.

Utilizing a production line method in a controlled environment produces less waste.

Quality assurance engineers ensure production standards, minimizing change orders.

Units are constructed in an organized process by skilled tradespeople.

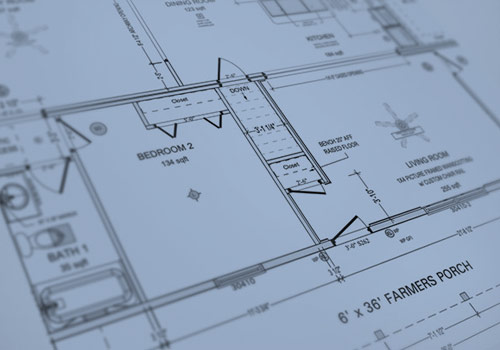

KBS engineers your idea into a custom design that meet your specific needs.

Gain architectural, structural, mechanical, and electrical expertise from one source.

Modular construction is unique in the construction industry. By leveraging a consistent, fixed environment KBS can accurately project timing and installation schedules. The controlled environment eliminates the unknowns and allows for faster delivery.

Many modular providers force you to use an existing set of plans or templates. This is not the case at KBS. From the beginning we work closely with our clients to produce a customized product built to their unique needs.

KBS Builders utilizes technology and automation to ensure quality and consistency. Engineers at KBS have expertise with Cadwork software and units built at the factory are produced in part with a CNC Saw by Hundegger. Parts produced on the saw are cut to spec from your exact drawings, eliminating waste and delays.